Related Tags

DIY Workshop: How to spray a 1950s-style cherry sunburst finish

Nothing beats the look of a late 1950s Les Paul Standard. Find out how to mix your own colours and spray your own sunburst using period-correct materials – and the best thing is you don’t even need specialist equipment.

All images: Huw Price

I first stripped and refinished this guitar a decade ago. It’s a 1983 Greco Mint Collection made with a leftover Super Real neck that I bought as a husk back in the days when you could pick these up for about £300. It was my first attempt at a Burst-style refinish and for a long time I’ve been feeling I could do a better job.

Having learned a few new skills in the past few years, I’m going to take things a bit further. As I’ve had the opportunity to play numerous examples from the 1950s my tastes have evolved – nowadays I prefer tops with moderate curly figuring and slim necks feel all wrong.

This time around, I’m veneering the top, but the big challenge is spraying a sunburst finish that looks closer to the Gibson examples of the 1950s. For this I’ll be showing how you can mix and spray your own lacquer without having to buy specialist equipment.

Strip down

We’re parachuting into this project at about the halfway point because I’ve covered many of the tasks before. In short, after stripping the finish using Nitromors, I remove the body binding and separate the fretboard from the neck to glue veneer onto the back of the ’board and increase neck depth. If you want to learn more about this, check out my Goldtop and Gretsch Anniversary conversion projects on Guitar.com.

I learned how to veneer a curved surface using a vacuum press when I was restoring my Gretsch. Later I did it myself using a vacuum storage bag when I needed to conceal the inlays and filled post holes on my Goldtop conversion. The difference with both those guitars is that they are veneered with single pieces, but for a Burst-style top, I need bookmatched veneer.

Some people do this by cutting the veneer to compensate for the curvature, but that strikes me as very challenging and possibly beyond my woodworking abilities. Instead, I decide to test the hypothesis that glued joints are actually stronger than wood fibres, and join the veneer pieces before gluing them onto the guitar.

The veneer I’m using came from eBay. It’s a surprisingly good source for materials of this sort and after searching for ‘figured maple veneer’, I chose the one I liked best. Although the veneer is only about 0.4mm thick, I approach joining the two pieces just as I would acoustic guitar back plates.

The veneer pieces are placed one on top of the other, aligned as closely as possible and clamped to a shooting board. I retract the blade on my longest plane, attach 320 grit paper using double-sided tape, and true up the edges with the plane laying on its side.

Conventional clamps are not an option for joining veneer sheets. Instead I butt the pieces up against each other, elevate one of the outer edges by a few millimetres and fix 10cm lengths of masking tape across the two pieces. With one piece elevated, it creates a gap beneath the strips of tape, and when they’re both laid flat, the masking tape actually becomes too short and its elasticity pulls the pieces together.

The veneer pieces are opened out so I can apply Titebond Original glue, and with such thin pieces of wood, it’s delicate work. I quickly lay the veneer sheets down on a flat board, with plastic packing tape under the join so the veneer won’t stick to the surface and the masking tape strips on the underside.

As I press the pieces flat, the masking tape pulls them together. I carefully inspect the join line to ensure the pieces are well aligned, then I place a flat piece of wood – again protected with plastic tape – over the join. This is clamped down to ensure the veneer remains as flat as possible. When I remove the clamps and the making tape, the result is almost perfect and I sand out any areas where there is misalignment.

Having learned a lot from veneering my Goldtop, I ensure that there is minimal overhang and strengthen the edges with masking tape to prevent the veneer from cracking around the sharp edge of the binding channel. I also apply fresh strips of masking tape across the join line as extra insurance against the veneer pulling apart under pressure. Having been unimpressed with Cold Press Veneer glue, I apply Cascamite with a roller. After 24 hours in the vacuum press, the veneer is bonded to the top.

Back together

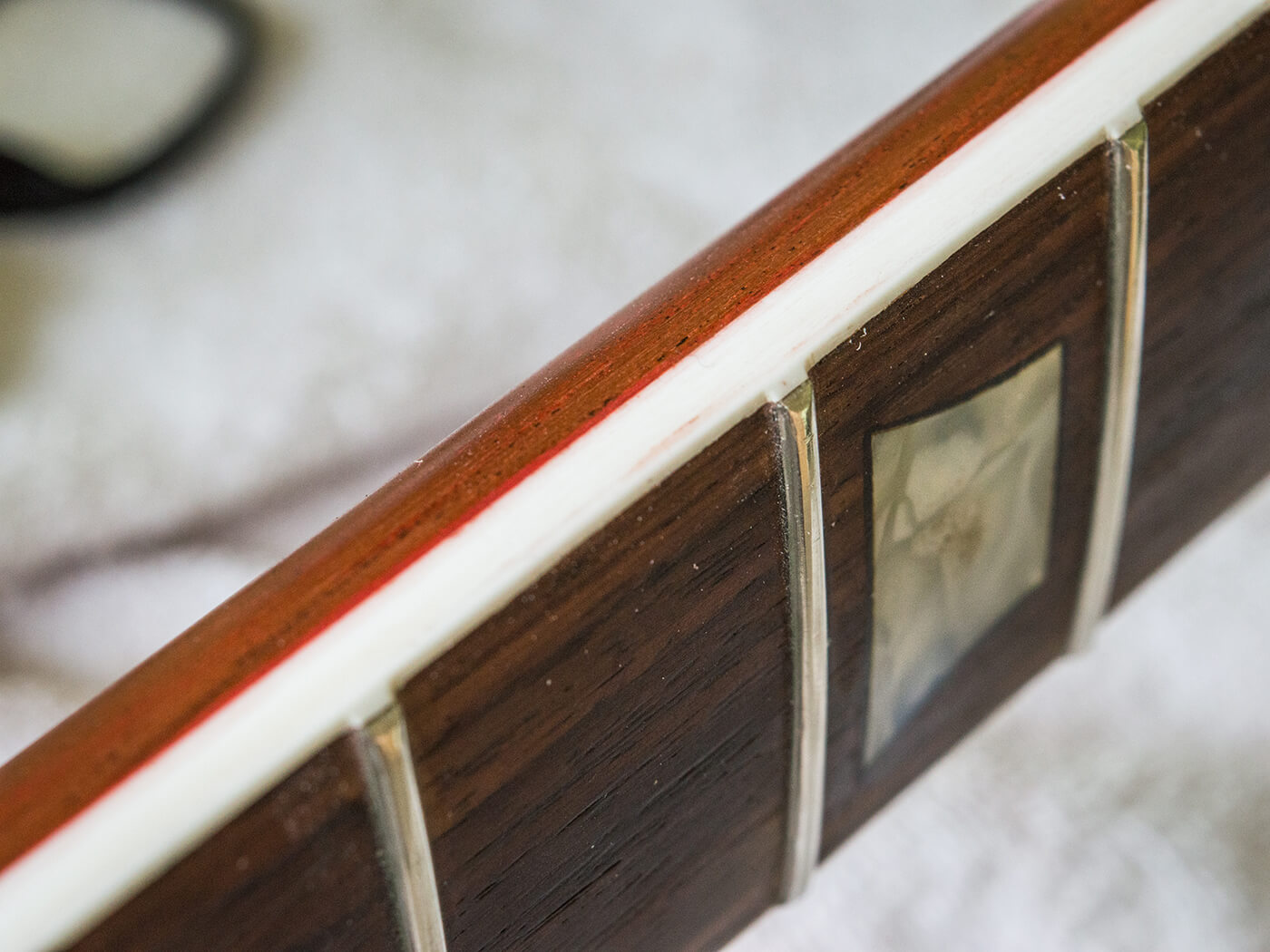

I clean up the veneer edges with a sharp chisel, remove any remaining residue from the binding channel and glue on the new binding. Finding off-white binding of the correct thickness for Grecos of this type is no easy task. I get mine from Eurospruce and it bends quite easily when heated.

Fresh fretboard binding is needed due to the increased depth, and a plastic tortoiseshell pick is sacrificed to make the side dots before the fretboard is glued back onto the neck – once the top veneer has been sanded level with the mahogany neck extension.

After the body and neck have been sanded, I reinstate the ground wire and tailpiece bushings, make a new nylon nut and put the guitar back together to test that everything is working properly before the finish is applied. I also prefer to finesse the neck profile with the guitar strung up, using templates I’ve taken from various 50s Les Pauls.

Seeing red

Gibson used red grain filler for 1950s Bursts and I decide to try Dartfords Thixotropic in cherry red. Grain filling is a messy and tedious process, but this stuff goes on and cleans up so nicely, it’s a pleasure. After leaving it overnight, it sands easily too.

Applying the filler onto bare wood also stains the mahogany, so the neck, binding and front of the body need to be masked off and protected before application. After sanding and wiping the body down with tack cloth, I remove all the masking tape, level the areas where the filler is raised adjacent to the tape lines, then apply fresh masking tape and protection for the front.

I start with a couple of mist coats of clear lacquer, and follow up with a couple of heavy coats of sanding sealer. These are flatted back with 320 grit paper to achieve a level surface before spraying colour coats.

Using Manchester Guitar Tech’s aniline cherry lacquer, I spray the neck and body with three coats. I’m pleased with the colour, but next time I might add a bit of black to the red grain filler to darken it very slightly.

Judging by my grain filler and lacquer tests on a scrap piece of mahogany, I’m confident it will look even better when some tinted clear coats are sprayed on top. I remove all the masking tape and the plastic that’s been protecting the binding and the front, and sand off any overspray.

Beginning to burst

Aniline dye’s tendency to fade is central to my strategy for tying to make the sunburst to look more like a vintage finish this time around, but first I need to mask off every part of the body that isn’t maple. Spraying begins with a couple of sealer coats that are sanded to ensure that the surface is perfectly flat.

From what I can establish, Gibson sprayed aniline yellow but here’s where things get complicated. Nobody sells aniline yellow lacquer in aerosols, so I’m going to be mixing my own. The issue is, how can you spray lacquer that you’ve tinted yourself unless you have a spray gun and compressor?

Fortunately, there are two solutions that are cheap and easy. The first is to buy a modelling airbrush and a tin of airbrush propellant. The total cost shouldn’t exceed £30 and they’re widely available.

The second is a Preval sprayer, which is basically an aerosol that screws onto a plastic vessel containing your lacquer. This allows you to buy tins or bottles of clear or coloured lacquer and replacement aerosol canisters are available separately. My Preval units come from morelli.co.uk and cost £6.48 each. The plan is to spray the sunburst colours using these two devices and spray the clear gloss coats using Manchester Guitar Tech’s clear gloss aerosols as usual.

Dyeing to know

Some alcohol soluble yellow aniline dye powder arrives from touchstonetonewoods.co.uk and it has to be dissolved to mix into the clear lacquer. I use isopropyl alcohol with a dash of acetone to aid the process. The powder dissolves almost instantaneously then it’s filtered through a 190-micron paint strainer as it’s added to clear lacquer. They look a bit like paper coffee filters and cost about 10 pence each on eBay.

The quantity of alcohol/acetone used to dissolve the dye should count as a part of your thinner mix. So, when cellulose thinners are added to the lacquer for spraying, you’ll need less than usual. A lacquer to thinners/solvent ratio of about 60:40 should be fine.

After spraying some test pieces with the aniline yellow, the results are closer to Gibson yellow than off the shelf amber or tinted clear. It really makes the grain pop and has a distinct golden hue, so I mask off everything that isn’t maple and use the Preval to cover the top. A couple of coats produces a strong yellow, and I’m banking on it toning down with a combination of fading and darkened top coats.

In the shade

The next bit may surprise you, but I apply a touch of edge shading before the red. For this I mix blue, medium brown and a hint of black into some cellulose thinners. It ends up a sort of RAF blue/grey and I add gloss cellulose in a 50:50 ratio to spray it with the airbrush. This allows me to apply a little at a time to achieve a greenish grey shadow around the edges and the resulting ‘unburst’ immediately makes the aniline yellow look mellower.

For the aniline red part of the bursting process I try the cherry I used on the mahogany over some maple veneer offcuts I have previously sprayed with the yellow and blue/black shading. I find it a little too dark and the aerosol’s tendency to spit could prove disastrous. Instead I try some pre-mixed aniline red from Eurospruce and when I spray it over the maple veneer, it looks about right.

To get a really smooth transition from yellow to red, good atomisation is needed. This means that the tinted lacquer exits as a very fine mist rather than larger droplets. My airbrush has better atomisation than aerosols and the Preval system, so that’s what I use.

Colour depth and shade can vary dramatically as lacquer dries and your perception will vary in different lighting conditions. My advice is to spray a little at a time and build the burst up gradually. So long as the lacquer is stored in an airtight container, it will keep and there’s no need to spray the whole burst at once if you’re new to this.

It seems convoluted, but being able to mix your own colours means that you should be able to get the exact look that you want – albeit with a little practice. I’m reasonably pleased with this sunburst from a technical perspective, but it’s odd to be intentionally spraying a ’burst that I don’t particularly like in the expectation – or hope – that natural processes will transform it into the finish I really want.

Some binding scraping and heavy coats of clear gloss bring this part of the process to a close. In the final instalment of this project we’ll discover if the aniline dye really does fade and how the overall look can be fine tuned using a very special tinted lacquer that you can make yourself. I’ll also be doing some relic’ing before reassembling, so check in soon to see the completed guitar.

For more DIY workshops and guides, click here.